Exploring the Latest Innovations in CNC Metal Cutting Machines

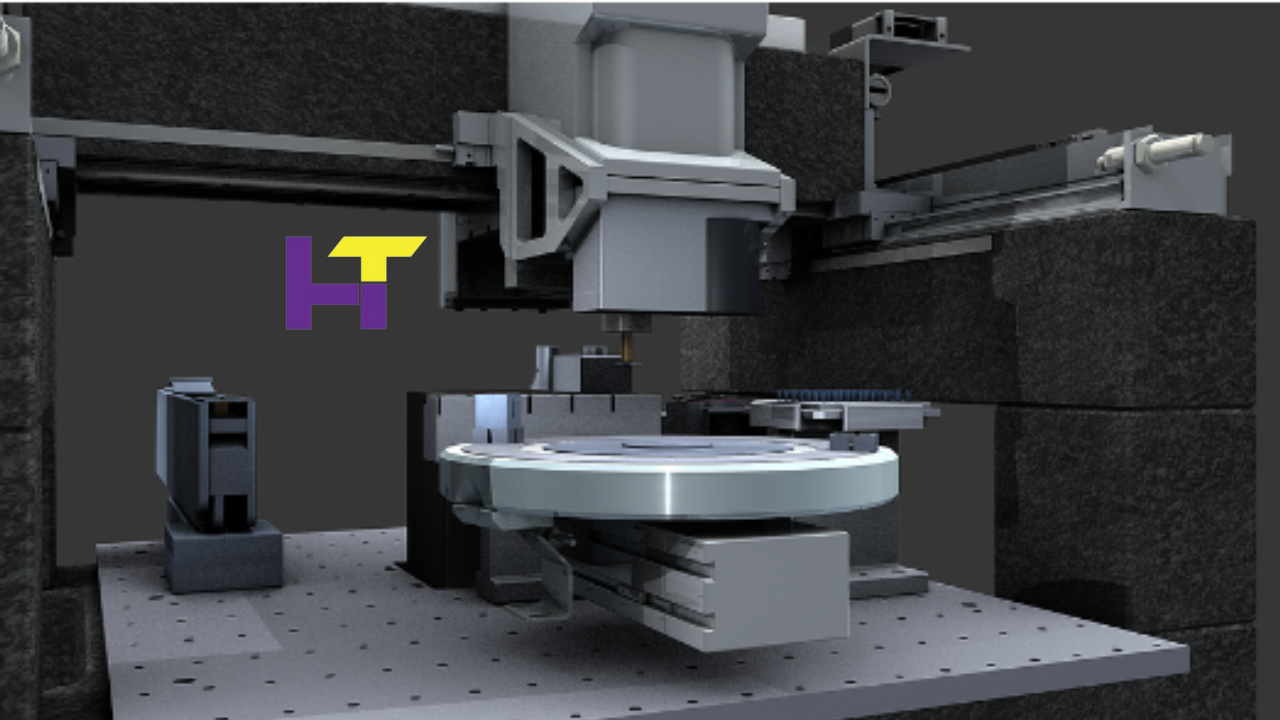

In today’s rapidly advancing technological landscape, CNC metal-cutting machines have become indispensable tools in the manufacturing industry. These machines offer precision, efficiency, and versatility in cutting various types of metals with ease. As technology continues to evolve, innovations in CNC metal-cutting machines are constantly being developed to enhance their capabilities and performance.

Advancements in Automation

One of the most significant innovations in CNC metal-cutting machines is the advancement in automation technology. Automation has revolutionized the way metal-cutting processes are carried out by increasing efficiency, reducing human error, and improving overall productivity. Modern CNC machines now have features such as automatic tool changers, robotic arms for material handling, and real-time monitoring systems that optimize the cutting process.

Integration of Artificial Intelligence

Another cutting-edge innovation in CNC metal cutting machines is integrating artificial intelligence (AI) technology. AI algorithms analyze data, predict cutting outcomes, and optimize tool paths for maximum efficiency. By harnessing the power of AI, CNC machines can now make intelligent decisions in real-time, leading to faster production times and higher accuracy in metal cutting.

Enhanced Precision and Accuracy

Recent advancements in CNC metal cutting machines have also focused on enhancing precision and accuracy in the cutting process. Newer machines are equipped with high-resolution sensors, laser measurement systems, and feedback mechanisms that ensure the exact dimensions and specifications of the metal workpiece are met with minimal margins of error. This level of precision is crucial for industries that require intricate and complex metal components.

Multi-Axis Machining

Multi-axis machining is another innovative feature that has gained popularity in CNC metal-cutting machines. Traditional machines were limited to three axes of motion (X, Y, and Z), but modern machines now offer five or more axes for increased flexibility and capability. This allows for cutting complex geometries and contours that would be impossible to achieve with traditional machining methods.

Advanced Cutting Tools

Advancements in cutting tool technology have also played a significant role in the evolution of CNC metal-cutting machines. New materials, coatings, and geometries have been developed to improve tool life, cutting speeds, and surface finishes. Carbide inserts, diamond-coated end mills, and high-speed steel cutters are now commonly used in CNC machining to achieve superior results in metal cutting applications.

Improved Energy Efficiency

With a growing emphasis on sustainability and energy efficiency, the latest innovations in CNC metal cutting machines have also focused on reducing energy consumption and environmental impact. Newer machines are designed to be more energy-efficient, utilizing advanced cooling systems, regenerative braking technology, and power-saving modes to optimize energy usage during operation. This lowers operating costs and contributes to a greener manufacturing environment.

Conclusion

In conclusion, the latest innovations in CNC metal-cutting machines have transformed the manufacturing industry by offering unprecedented precision, efficiency, and versatility. From advancements in automation and artificial intelligence to enhanced precision, multi-axis machining, advanced cutting tools, and improved energy efficiency, these innovations continue to push the boundaries of what is possible in metal-cutting technology. As technology evolves, we can expect even more groundbreaking developments in CNC metal-cutting machines that will further revolutionize the way metal components are fabricated.

Read More: Navigating the World of CNC Manufacturing: A Comprehensive Guide.